- Stick electrodes 9

- MIG/MAG solid wires 5

- TIG rods 2

- MIG/MAG flux-cored wires 50

- Hardfacing 21

- Solders & fluxes 1

- Polymer coatings 9

- Welding equipment 1

- Welding torch 4

- Plasma cutting 7

- Thermal spraying 1

- Oxyfuel technology and gas supply 4

- Welding accessories 4

- Cut-off and grinding wheels 2

- Occupational health and safety 5

for aluminum and aluminum alloys

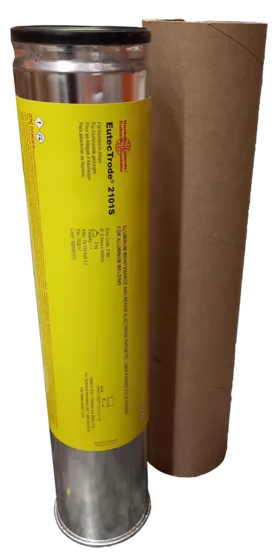

Castolin 2101 Super

The flux-coated stick electrode produces a Si-alloyed Al-based weld metal. Easy ignition. Slag cannot be welded over. Smooth and finely flaked weld seams.

Technical data

EN ISO 18273: E - Al 4047 (AlSi 12)

Material no.: 3.2585

Applications

For joining and build-up welding of aluminum, AlSi alloys and AlSi cast materials

up to 12 % Si and for repairs.

Typical applications are

Housings for machines, pumps, compressors, gearboxes and engine blocks, oil pans, oil coolers, protective covers, pistons, mold boxes, pulleys and handwheels.

Processing instructions

Remove cracked and other damaged material as well as existing casting skin. Clean welding areas. During welding, adjust the heat input to the component, its material and dimensions, preheat solid workpieces to 150 - 200 °C.

The electrode can also be gas-welded if necessary.

Remove all corrosion-promoting slag after welding. For better slag removal

chemical post-treatment in a 10 - 20 % caustic soda solution (50 - 80 °C / 1 - 2 min.) is recommended. For rinsing, use 20 - 30 % nitric acid and then water.

Welding positions: PA, PB

Type of current: = (+)

Specification

| Code | 2101S 2502 |

|---|---|

| Category | Aluminum |

| Number in package | 2.0 kg |

| Price per unit | €74.63 / kg |

| Price excl. VAT | €149.26 |

| Price incl. VAT 23% | €183.59 |

| Availability | within 7 to 10 days |